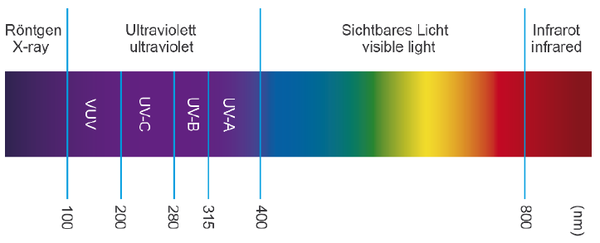

| UV Spectrum |

UV radiation is part of the spectrum of electromagnetic radiation. It follows the short-wave of visible light. According to DIN 5031, Part 7 (Deutsche Industrie-Norm – German Industrial Standard) the spectrum is segmented as demonstrated in the table and diagram below. Depending on the application, a different part of the spectrum is required. For example: Inks (UV-C, UV-B), Laquers (UV-C, UV-A, UV-VIS), Adhesives (UV-A, UV-C), Pottant (UV-A, UV-C), Polyester resins -foils (UV-A, light - blue), Polyester resins -foils i.e. glass fibre stabilised (light - blue, UVA). Medium pressure mercury vapour curing lamps, emit a high intensity, broad band mercury spectrum as standard, they are also sometimes known as "365nm lamps" or "high pressure lamps".

| UV-C | = 100 to 200 nm (vacuum-UV) = 200 to 280 nm (far UV) |

| UV-B | = 280 to 315 nm |

| UV-A | = 315 to 400 nm (in DIN only defined to 380 nm, in practice often down to 400 nm) |

| UV-VIS | = 400 to 450 nm (395 to 445 nm are; defined in DIN) |

| Light (VIS) | = 380 to 780 nm (in practice often between 400 and 780 nm) |

Represented pictorially:

Different spectrums can be created by adding rare earth metals ("doping") to the lamp to change its spectral output. For example Iron doped medium pressure mercury vapour lamps, often referred to as UVA spectrum lamps, "metal halide lamps" or "D" bulbs, are mainly used when a deeper cure is required or for clear varnishes, coatings, adhesives or lacquers. They are also more popular in Asia, as the chemistry of inks and coatings in that region is sometimes more suited to this kind of lamp. Gallium doping can also be added to give a deeper cure and avoid the absorption of UV by Titanium Dioxide, an additive often used in white coatings, either in printing or in the furniture coating industries. Sometimes referred to as "white cure bulbs" or "V" bulbs, these lamps produce a "UV Visible" or UVV spectral output.

Standard medium pressure mercury vapour lamps are sometimes known as "H or H+" bulbs, give a good all round cure under most circumstances and also produce a high level of UV energy in the shorter ~ 254nm UVC wavelengths which offer a better surface cure and can also be used in conjunction with an additional Gallium doped lamp for example in a 2 lamp system to provide a good surface and depth cure in special applications. In summary, this means that the lamp can be specifically matched to special or "non-standard" inks or coatings with different photo initiator sensitivities, such as UV LED inks, Whites and thick lacquers or adhesives. Please see list for spectral options to match to your coating or ink manufacturer's specification.

Spectral Graphs

Please see the downloadable information located on this page for spectral graphs. Alternatively, please don't hesitate to get in touch for further support. Contact our technical team on +44 (0)1582 805410 or email info@uv-technik.co.uk.

| Standard Lamp Spectrum |

| |

| |

| |

| Doped Lamp Spectrum |

| |

| |

| |

| |

| |

| Quartz Transmission |

| |